Revolutionize Your Manufacturing with Advanced MES Solutions

Leading the way in Industry 4.0 with innovative IoT and AI solutions that drive efficiency, automation, and intelligence.

Integrate IoT and AI to enhance productivity, streamline processes,

and automate documentation with our cutting-edge Manufacturing Execution System

Streamline Your Manufacturing Processes

Automate multiple processes within your industry to boost efficiency and reduce operational costs

Equipment Automation

Real-Time Data Monitoring: Continuously monitor equipment performance and health.

Predictive Maintenance: Use AI to predict and prevent equipment failures before they occur.

Remote Control: Manage and control machinery remotely for increased flexibility.

Process Automation

Automated Workflows: Design and implement automated workflows to streamline operations.

Quality Control: Automate quality control checks to ensure consistent product standards.

Inventory Management: Use IoT to manage inventory levels and automate replenishment.

Production Scheduling: Optimize production schedules for maximum efficiency.

Mobile Platform

We provide mobile device access to the shop-floor teams to enhance Manufacturing Execution System (MES) applications. By providing real-time access to production data and workflows, mobile devices can enable operators and production staff to easily track and manage production processes, inventory, and quality control. For example, workers can use mobile devices to scan QR codes or RFID tags to track inventory movement, monitor production lines, and access training manuals and quality control procedures.

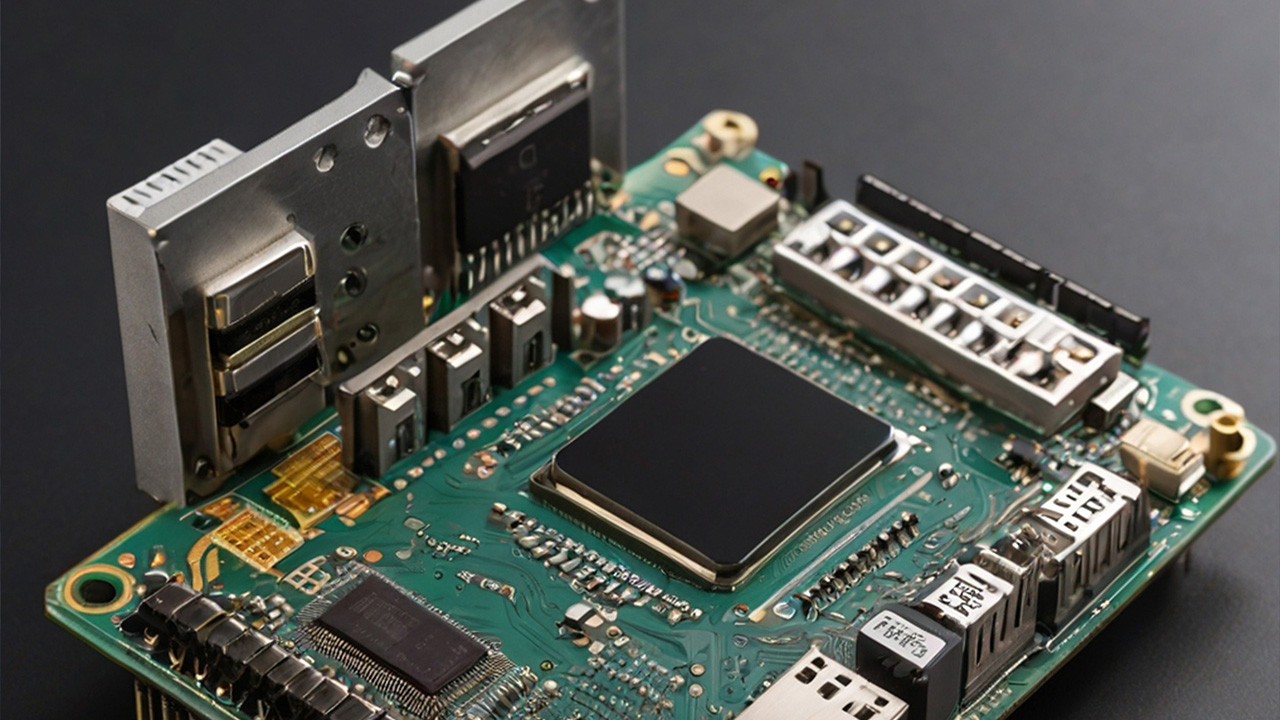

Integrated Hardware & Software Platform

IoT devices are seamlessly integrated with software applications to provide real-time visibility on shop-floor operations. By connecting IoT devices such as sensors, RFID tags, and barcode scanners to a manufacturing execution system (MES) or enterprise resource planning (ERP) software, manufacturers can gain real-time visibility into production processes, inventory levels, and equipment performance. This data can be used to track production lines, monitor equipment downtime, and optimize production schedules.